The 2.5-ton mine-used lithium battery electric locomotive has a cargo capacity of about 20-25 tons on a slope of 3‰ (the weight of the mine truck and the weight of the locomotive should be calculated.)

1. Product model, meaning and carrying capacity introduction (2.5 Ton Lithium Mine Battery Locomotive)

The 2.5-ton mine-used lithium battery electric locomotive has a cargo capacity of about 20-25 tons on a slope of 3‰ (the weight of the mine truck and the weight of the locomotive should be calculated.)

2. Inquiry notice

Configuration selection: When selecting a 2.5-ton lithium battery electric locomotive for mining, it is necessary to select the speed regulation mode and gauge.

The speed control methods include: Resistance control, IGBT control

The gauge is divided into three types: 600, 762 and 900 or as required

Special customization: The standard 2.5 ton electric locomotive uses a 3.5 KW DC motor. If the mine environment gradient is greater than ‰3, its traction will be affected (the normal gradient cargo capacity is about 20-25 tons, which may cause The load capacity of the

locomotive is reduced). Therefore, in order to meet the requirements of different mine environments and high requirements for cargo capacity, we can customize the heavy-duty type. Please explain the situation or provide the demand with the salesperson when ordering. Our

company will give the plan according to the requirements.

If you don’t know how to select you can provide Mine Humidity,Dust, Transportation Distance,Number Of Bends, Load Weight ,Working Hours Of A Shift Working, And Other Specific Working Conditions so that we can help you choose the most suitable Battery Electric locomotive.

3. Brief introduction of mine lithium battery electric locomotive

The CTY2.5/6GB mine-used lithium battery electric locomotive belongs to the second generation product, which has the characteristics of simple structure and reliable operation. For locomotives that use IGBT chopper speed regulation, the main circuit of the chopper has a

strong shut-off capability, and the trigger circuit uses an integrated voltage stabilizer source, integrated timer, combined components, etc., so that the entire circuit has fewer components, easy installation, and easy debugging. Reliable work. Using lithium battery power supply

device, maintenance-free fast charging, long battery life, and labor saving.

4. The use conditions of the mine lithium battery electric locomotive electric locomotive

1. The altitude does not exceed 1200m.

2. The highest temperature of the surrounding air is +40℃, and the lowest temperature is -20℃.

3. The average maximum relative humidity of the wettest month is 95% (the average minimum temperature of the same month is not more than +25℃).

4. In mines that do not contain gas or explosive gas.

Locomotive Avantage Please Click: Locomotive Advantages.

5、Operation Video

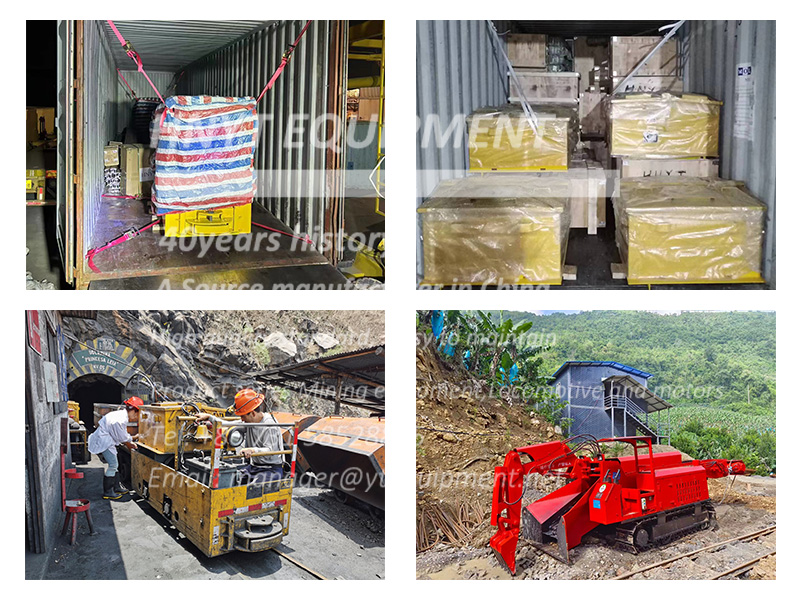

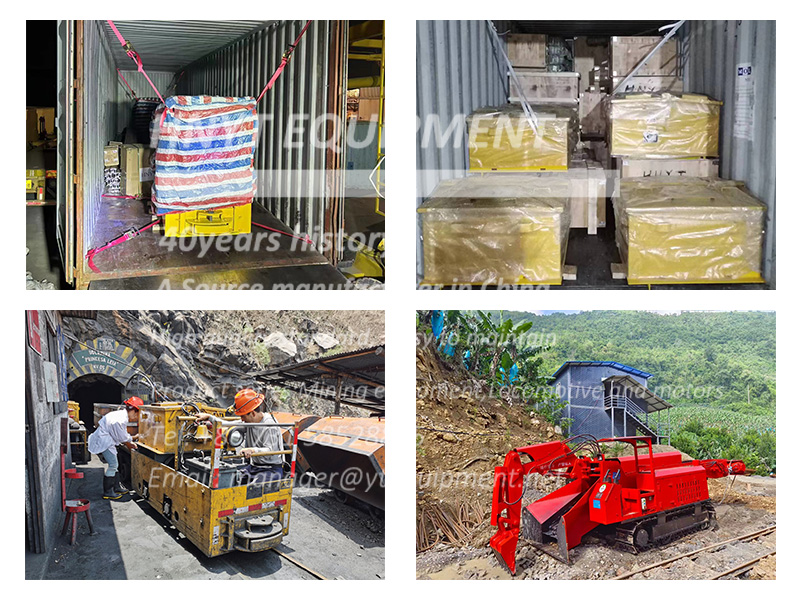

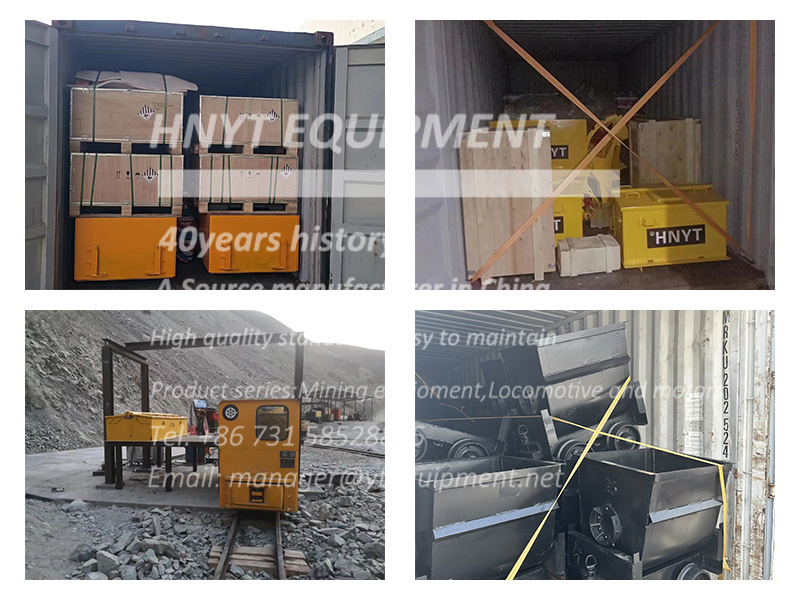

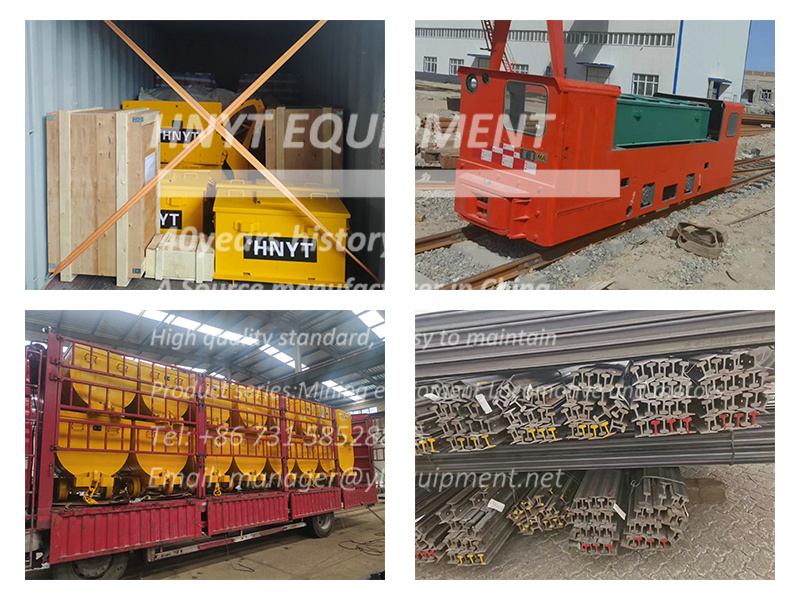

Shipment and one site details

←No Information

Technical Specification

| Model | CTY2.5/6、7、9G(B) | ||||

| Dead weight | 2.5t | |||||

| Track gauge | 600、762 or 900mm | |||||

| Traction force | 2.55kN | |||||

| Max traction force | 6.13kN | |||||

| Speed | 4.54km/h | |||||

| Battery device | Lithium battery | 51.2v 300ah | ||||

| Lead acid battery | 48V330AH | |||||

| Motor power | 3.5kW×1 | |||||

| Dimensions | Length | 2330mm | ||||

| width | 914、1076 or 1212mm | |||||

| Height | 1550mm | |||||

| Wheelbase | 650mm | |||||

| Wheel diameter | Φ460mm | |||||

| Min turn radius | 5m | |||||

| Controlling way | Resistance or IGBT chopper | |||||

| Brake way |

Mechanical brake | |||||