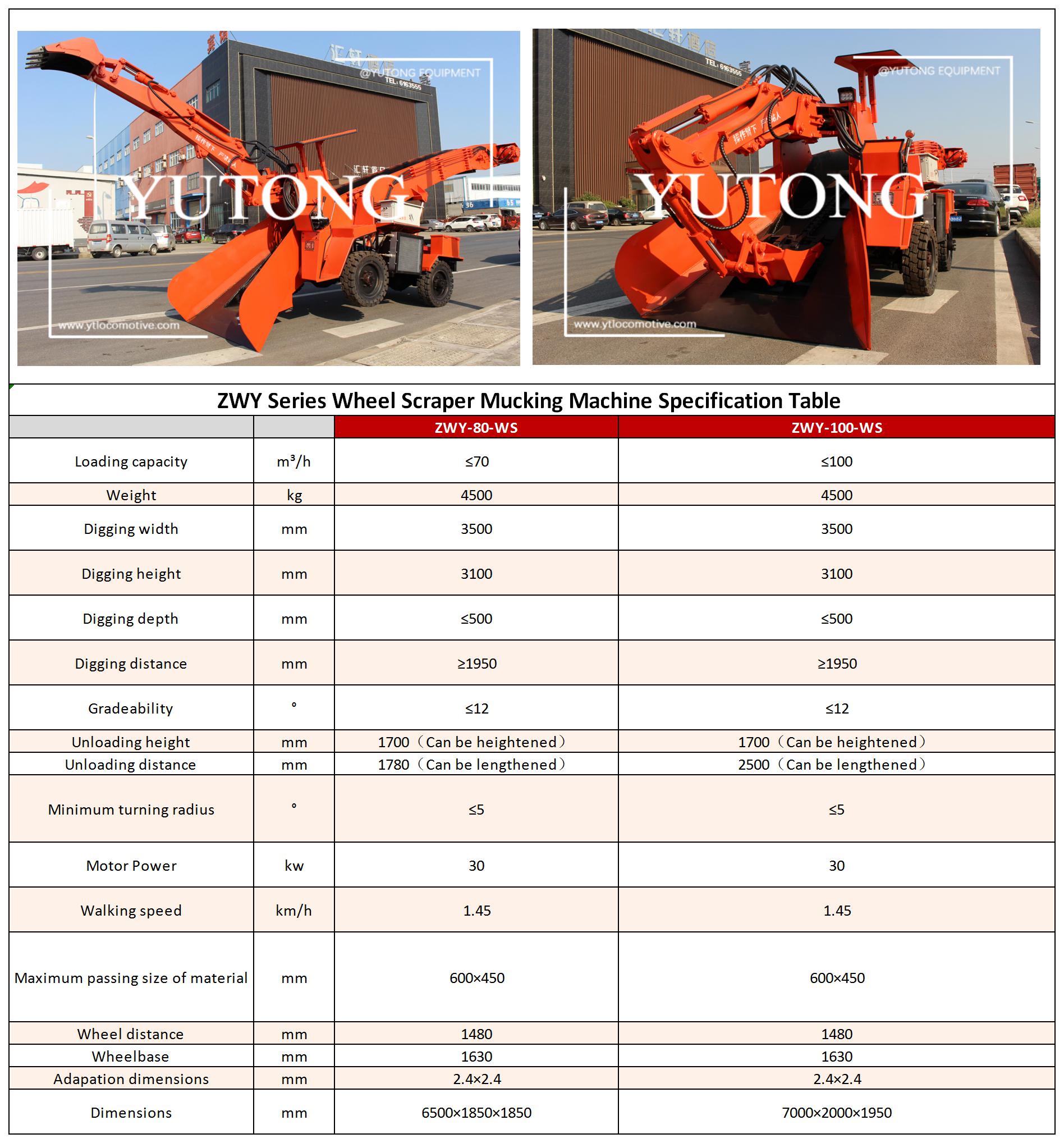

Copper mine applicated The wheel scraper mucking loader is suitable for large medium and small roadways with a working section of 2.4*2.4m or more and a slope of about 12. Mainly used in coal mines and non-coal mines water diversion tunnel projects and urban pipe network supplier

The wheel scraper mucking loader is suitable for large medium and small roadways with a working section of 2.4*2.4m or more and a slope of about 12°. Mainly used in coal mines and non-coal mines water diversion tunnel projects and urban pipe network tunneling and loading operations. The working principle is to excavate and transport various ore and slag materials and directly load them into wagons agricultural vehicles or other transportation equipment. It greatly improves work efficiency and is an ideal mechanized slagging equipment for mines and tunnels.

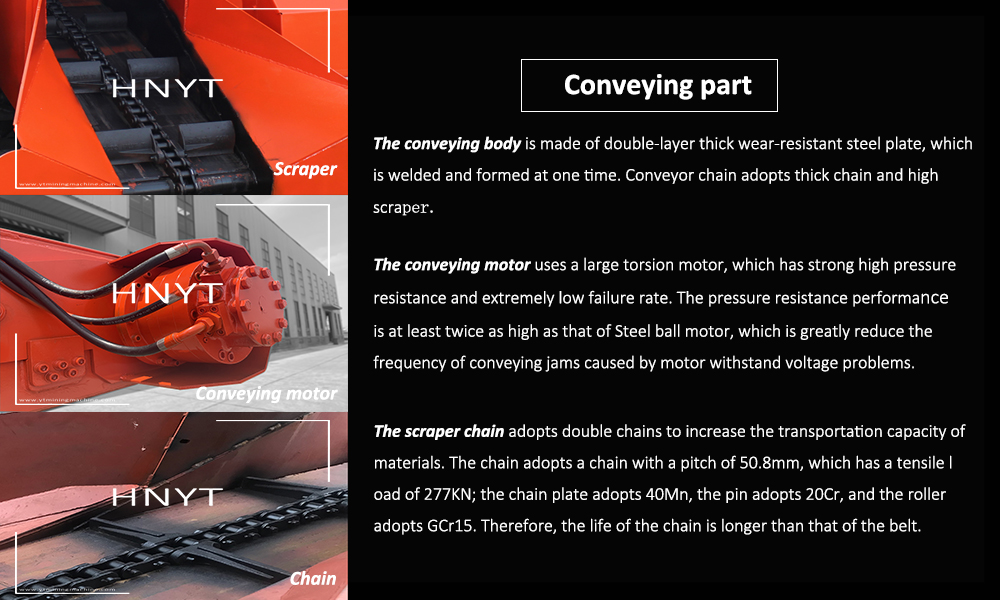

This series of slag scraper adopts four-wheel drive thick chain high and low scraper conveying and the integral conveying trough body welded by high-strength steel plate. The service life and effect are much higher than that of belt conveying. This model is the price of a wheeled machine and the function of a scraper machine achieves high quality and low cost. The structure is compact the driving force is large the picking range is wide the lifting positioning is accurate the material transportation speed is fast and the rock can be loaded in a comprehensive section without leaving dead corners. No need for manual assistance to clean up the working surface.

Main Features of Mucking Loader

1) Load sensing hydraulic priority to, stable and reliable, energy conservation and significant.

2) Durable, each gear ratio reasonable matching, reduce the power consumption.

3) Reduce the power consumption.

4) Simple structure and reliable performance.

5) semi-enclosed assembling,easy to maintain.